The most impressive laser (micro)machining results have come from a femtosecond laser system. If you have an interest in using this tool, please contact Richard Shafer at richard.shafer@ien.gatech.edu.

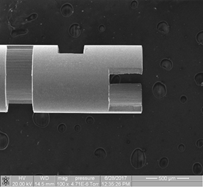

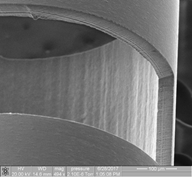

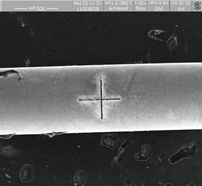

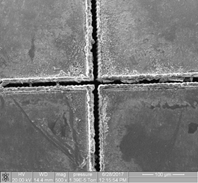

Picture A Picture B Picture C Picture D

Femtosecond Laser:

In the last 10 years, femtosecond lasers have moved out of the laboratory and into industrial use for micromachining because they offer several advantages over longer pulsed lasers. The femtosecond laser allows processing to be extended to transparent materials using a multi-photon process whereby the high energy short pulse is focused into the material and thereby changes the characteristics of the material allowing selective etching or ablation techniques never available with the long pulse lasers. The above photos show cuts made with a femtosecond laser (A and B) on a Nitinol tube that has an 80µm wall thickness and comparison to cuts made by a microsecond laser (C and D; similar to existing capabilities at IEN). The first pictures (A and B) show the cleanliness of the femtosecond laser cuts while the second set (C and D) show the common recast deposition from a microsecond laser. The spot size of the IR laser is 6um to 15um with the ability to work on substrates from 1um to 20mm. Common materials that can be machined by the femtosecond laser are:

Polymers

Polyethylene ♦ Nylon ♦ Pebax ♦ PMMA ♦ PVAC (Poly (vinyl acetate)) ♦ PVDF (Polyvinylidene Florine) ♦ PEEK (Polyether Ether Ketone) ♦ Polycarbonate ABS (Acrylonitrile Butadiene Styrene ♦PEN (Polyethylene Naphthalate) ♦ COC (Cyclic Olefin Copolymer)/COP (Cyclic Olefin Polymer) ♦ PI (Polyimide) ♦ Polyurethane ♦ Silicone ▪PET (Polyethylene Terephthalate) ♦Polystyrene ♦ Pellethane ♦Parylene

Bioresorbable Polymers

PLLA (Poly-l-lactic Acid) ♦ PLC (Polycaprolactone) ♦ PGA (Polyglycolic Acid)

Ceramics

Alumina ♦ Zirconia ♦ PZT ♦ Silicon Carbide ♦ Aluminum Nitride♦ Tungsten Carbide

Metal

Stainless steel ♦ Tantalum ♦ Tungsten ♦ Nitinol ♦ Cobalt ♦ Platinum ♦ Molybdenum ♦ Titanium

Glass

Borosilicate ♦ Sapphire ♦ Diamond ♦ Ruby ♦ Pyrex ♦ BK7 ♦ Soda Lime Glass

Please let us know if you have additional questions concerning Institute for Electronics and Nanotechnology cleanroom or associated labs.