This section contains the standard dielectric etch recipes for all GT RIE and ICP equipment: Vision RIE 2, Vision RIE 1, Oxford End-Point RIE, Unaxis 790 RIE, Plasma Therm RIE (Right Chamber), and Plasma Therm ICP (Left Chamber).

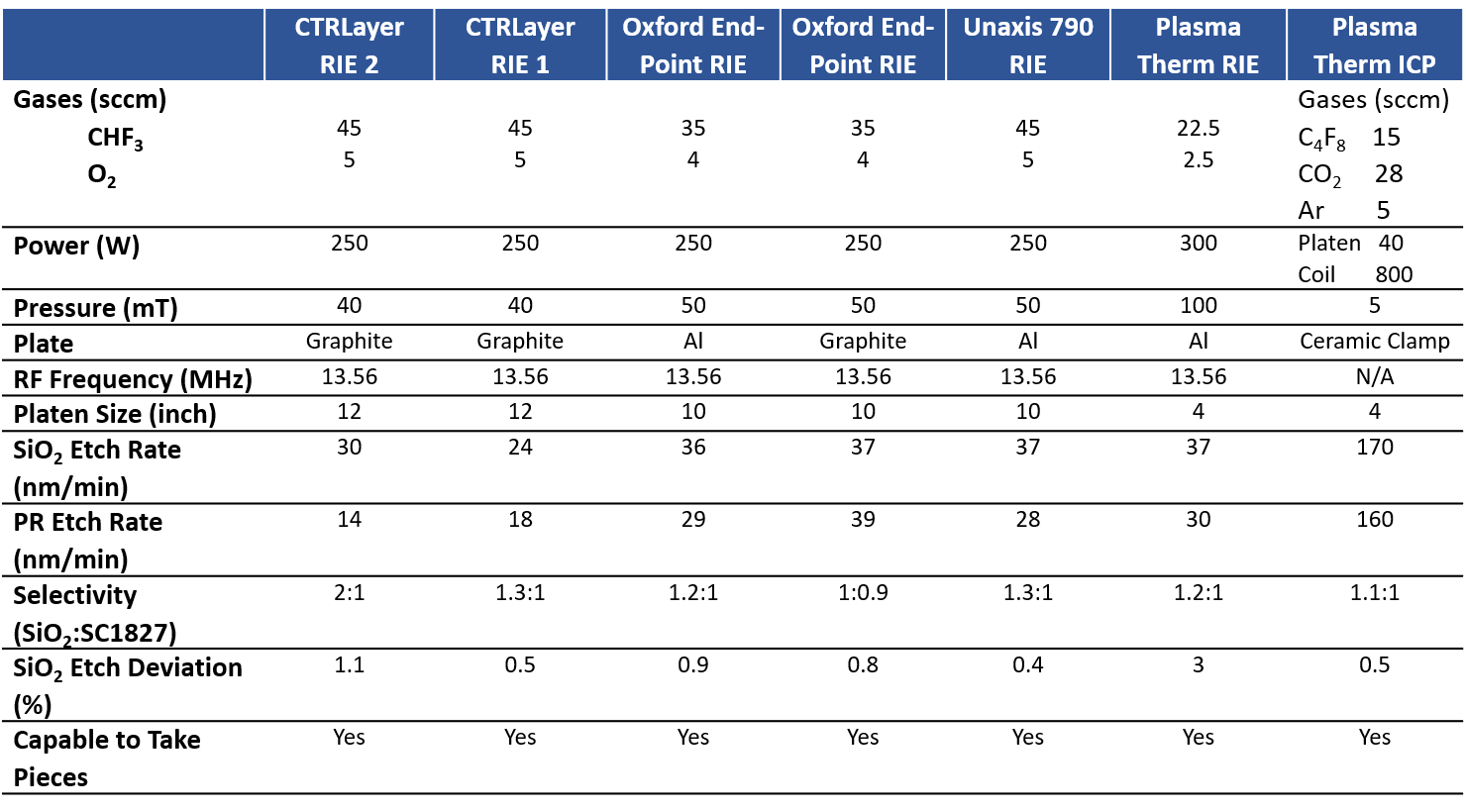

Comparison of Oxide Etch Details for GT RIE and ICP Equipment

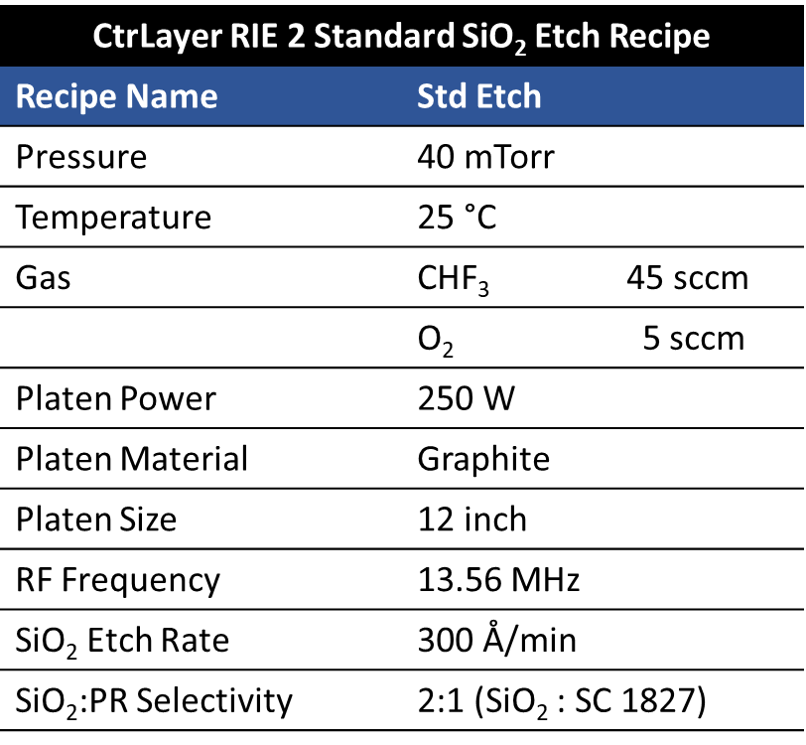

Vision RIE 2

- Location: Marcus Cleanroom

- Etching Capabilities:

- Sample size:

- Pieces to 8” wafer

- Up to four, 4” wafers or a single 6” wafer at one time

- Standard Recipes:

(Back to top)

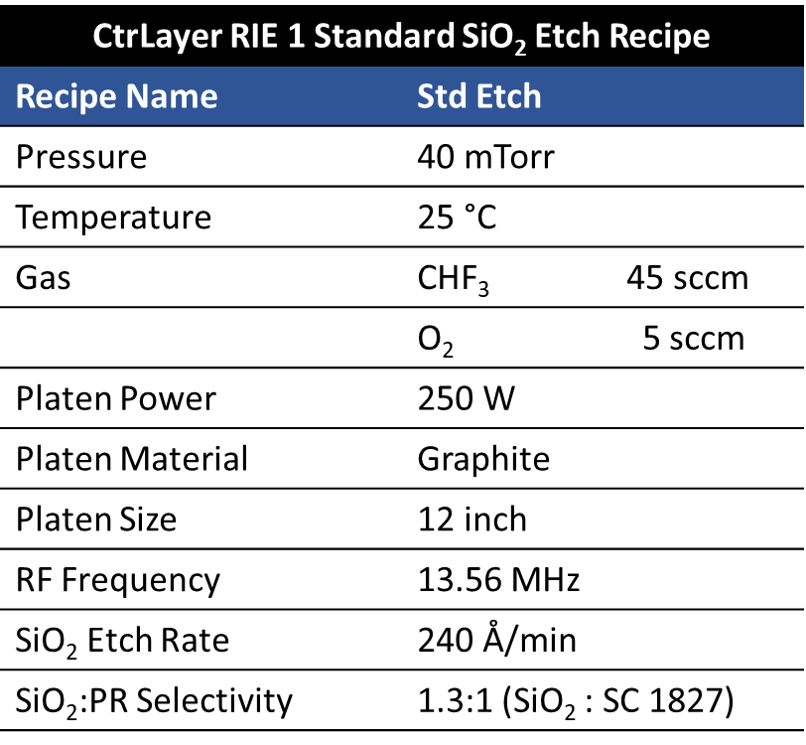

Vision RIE 1

- Location: Marcus Cleanroom

- Etching Capabilities:

- Sample size:

- Pieces to 8” wafer

- Up to four, 4” wafers or a single 6” wafer at one time

- Standard Recipes:

(Back to top)

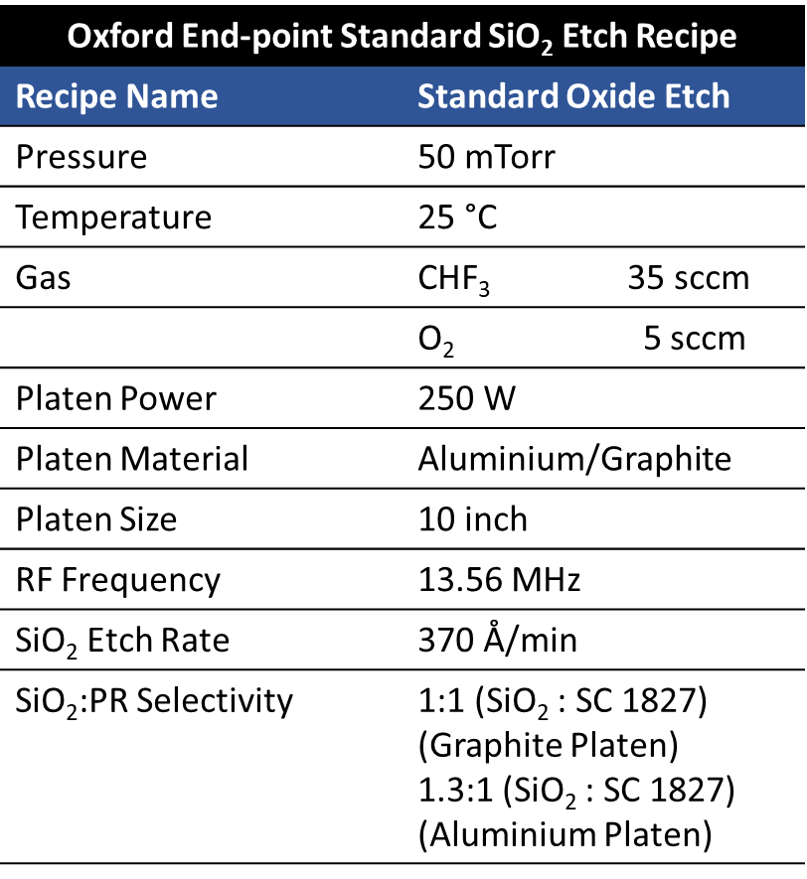

Oxford End-Point RIE

- Location: Marcus Cleanroom

- Etching Capabilities:

- Sample size:

- Standard Recipes:

(Back to top)

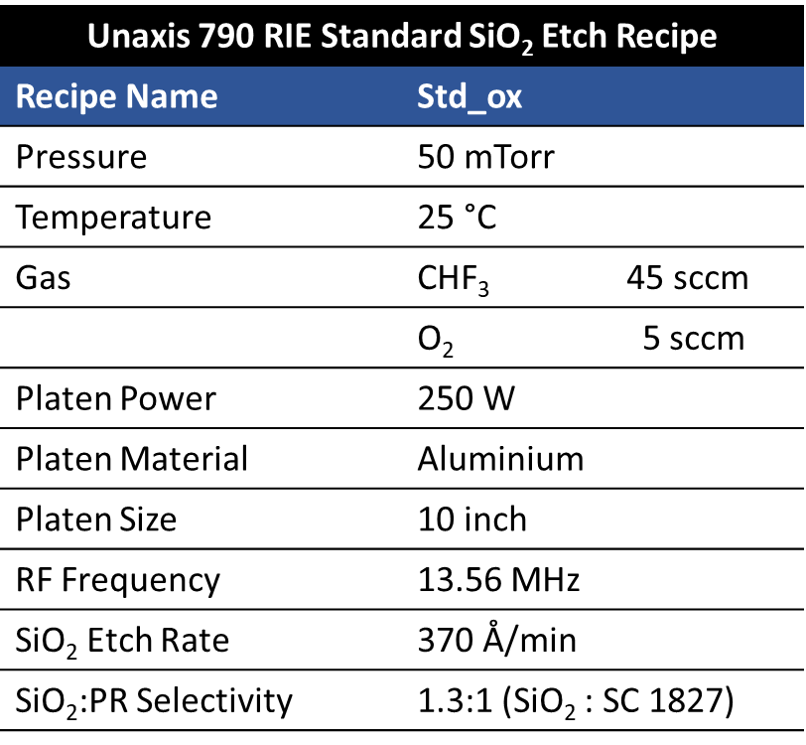

Unaxis 790 RIE

- Location: Marcus Cleanroom

- Etching Capabilities:

- Sample size:

- Standard Recipes:

(Back to top)

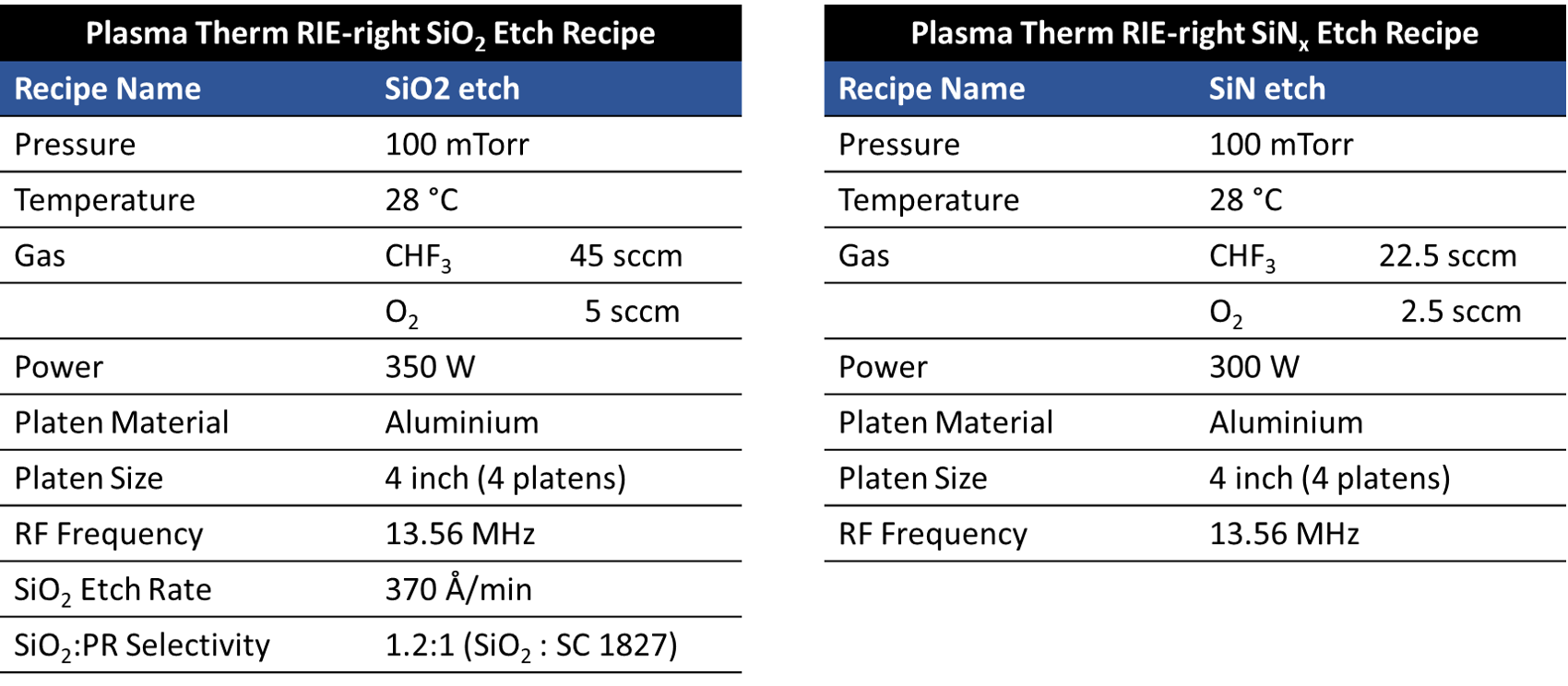

Plasma Therm RIE (Right Chamber)

- Location: Petitt Cleanroom

- Etching Capabilities:

- Sample size:

- Pieces to 4” wafer

- Up to four, 4” wafers at a time

- Standard Recipes:

(Back to top)

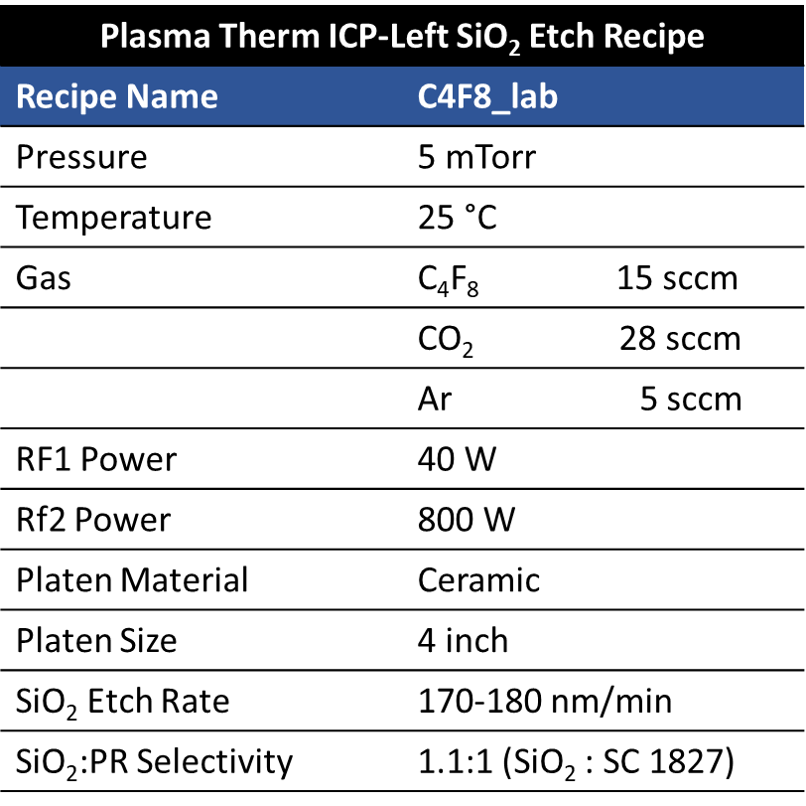

Plasma Therm ICP (Left Chamber)

- Location: Petitt Cleanroom

- Etching Capabilities:

- Sample size:

- Pieces to 4” wafer. Pieces has to be placed on a four inch Si wafer with cool grease, or with a kapton tape

- Standard Recipes:

(Back to top)