This section contains the standard annealing/growth/doping processes for all GT IEN equipment :Tystar Nitride, Tystar Poly, Lindberg Furnaces, Tystar Mini, MRL furnace, CtrLayer SEF Sulfurization Furnace, FirstNano Graphene Furnace 1, FirstNano Graphene Furnace 2, JetFirst RTP, SiGe Nanowire Furnace, SSI RTP

Pettit Cleanroom

Tystar Nitride

- Sample size: Pieces to 6” wafers

- Tube 1: n-type doping

- Tube 2: p-type doping

- Tube 3: Padox, Well, Field (LOCOS) oxide growth

- Tube 4: LPCVD silicon nitride

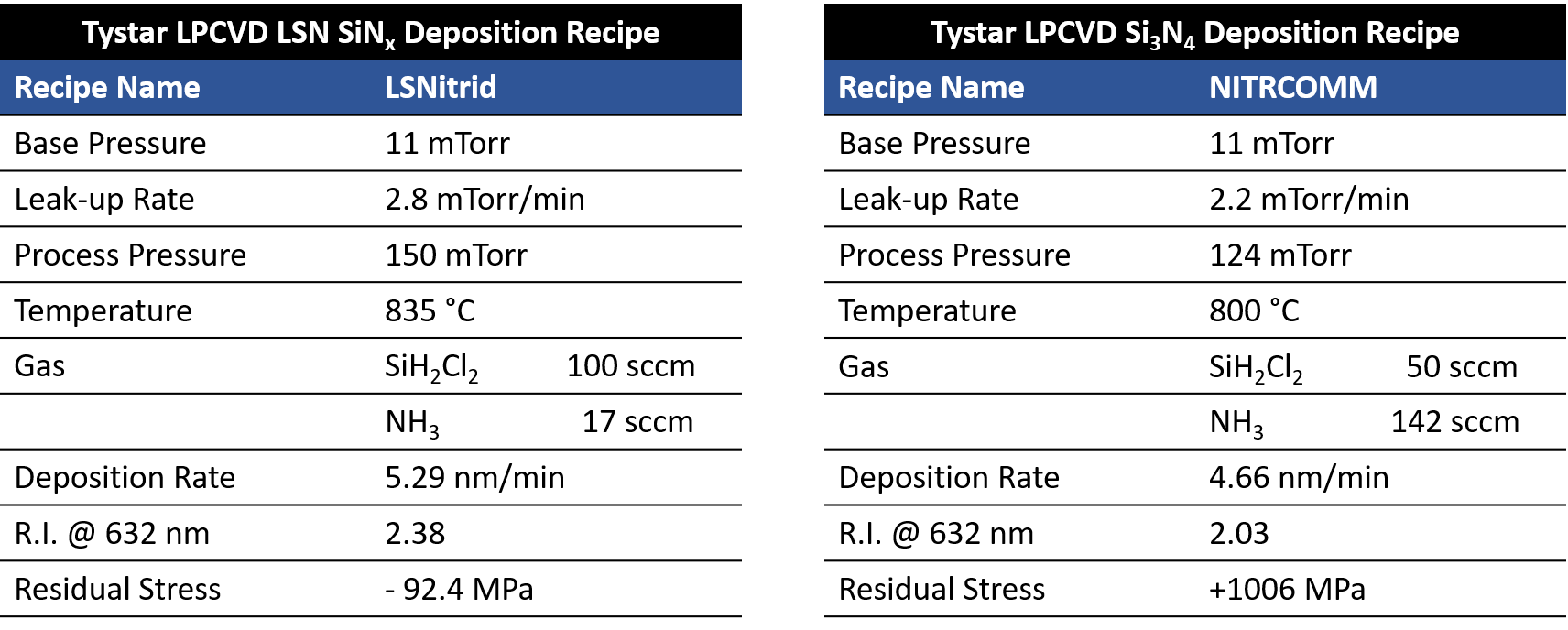

Recipe for Tystar Nitride Tube 4, LPCVD Silicon Nitride

Tystar Poly

- Sample size: Pieces to 6” wafers

- Tube 1: LOT/implantation anneal

- Tube 2: Kooi, p-well drive, and dry oxidation

- Tube 3: Polysilicon deposition, n-doped polysilicon

- Tube 4: Polysilicon deposition, p-doped polysilicon

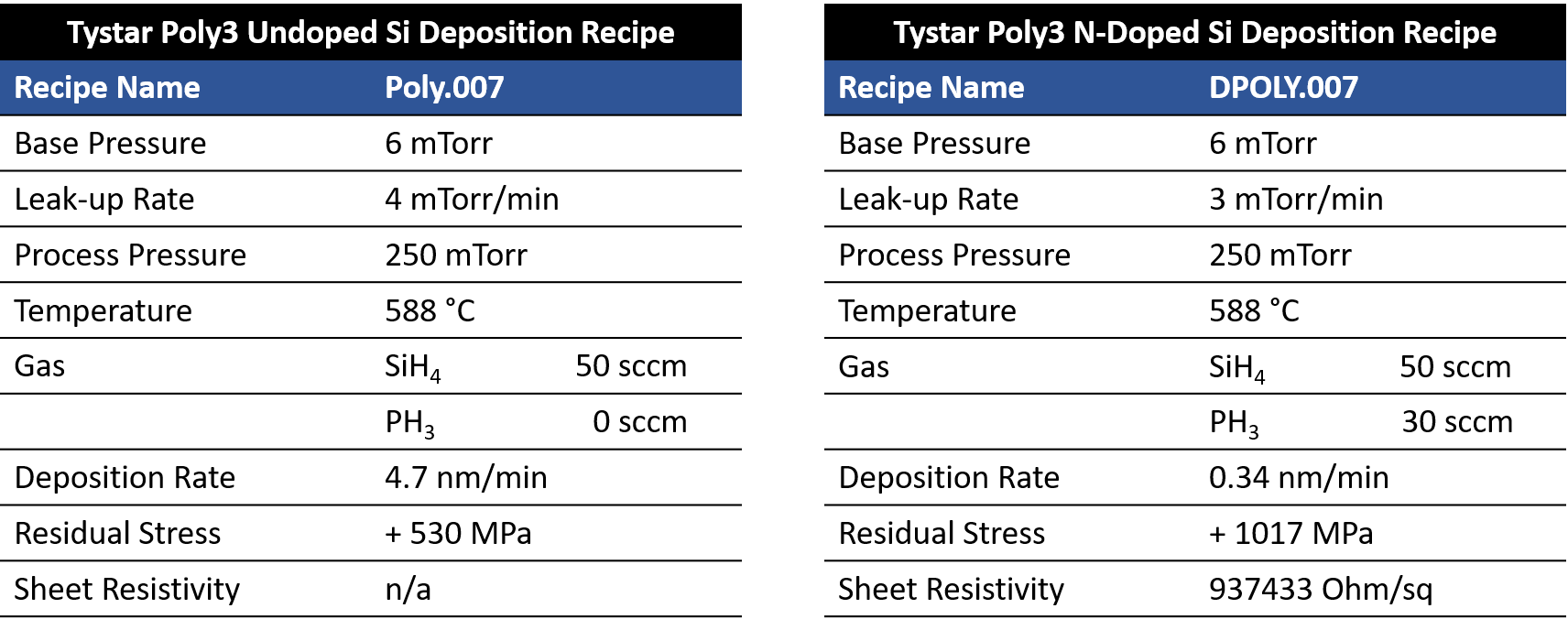

Recipe for Tystar Poly Tube 3: LPCVD Polysilicon

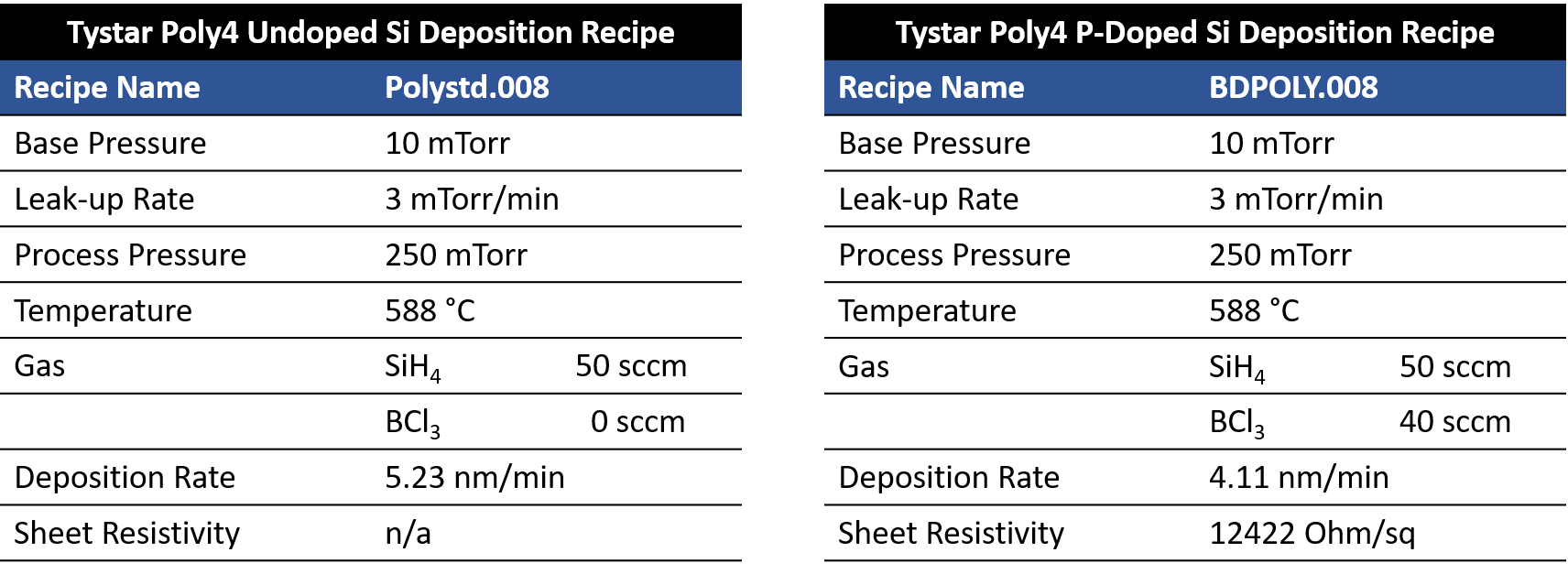

Recipe for Tystar Poly Tube 4: LPCVD Polysilicon

Lindberg Furnaces

- Sample size: Pieces to 6” wafers

(Back to Top)

Marcus Inorganic Cleanroom

Tystar Mini

- Sample size: Pieces to 4” wafers

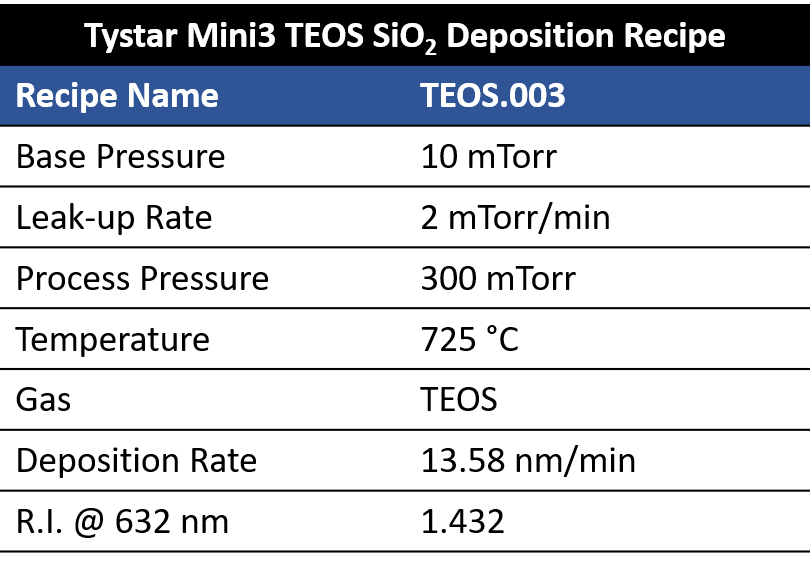

Recipe for Tystar Mini Tube 3: TEOS Deposition

MRL Furnace

- Sample size: Pieces to 6” wafers

CtrLayer SEF Sulfurization Furnace

- Used to deposit sulfur at high temperatures

- Maximum temperature: 1050 °C

- Ramp rate: Up to 120 °C/min

- Gases: Argon, hydrogen, methane

FirstNano Graphene Furnace 1

- Quartz chamber with graphite internals

- Sample size: pieces to 3” wafers

- Temperatures up to 2200 °C

- Fully Programmable

- Turbo pumped

FirstNano Graphene Furnace 2

- Configured to grow graphene on copper foil

- Quartz chamber with graphite internals

- Sample size: pieces to 4” wafers

- Temperature up to 1150 °C

- Gases: Silane, hydrogen, argon, ammonia

- Turbo pumped

SiGe Nanowire Furnace

- Silicon nanowire growth

- 900 °C max

- Infrared heating

- Substrate size: pieces up to 4” wafers

- Gases: Argon, hydrogen, 100% SiH4, Trimethylboron, PH3, Ge

SSI RTP

- Rapid thermal processing

- Sample size: pieces to 4” wafer

- Max temperature 900 °C

- N2/air/O2 ambient

- 10 SLM (10000 sccm) range MFCs

(Back to Top)