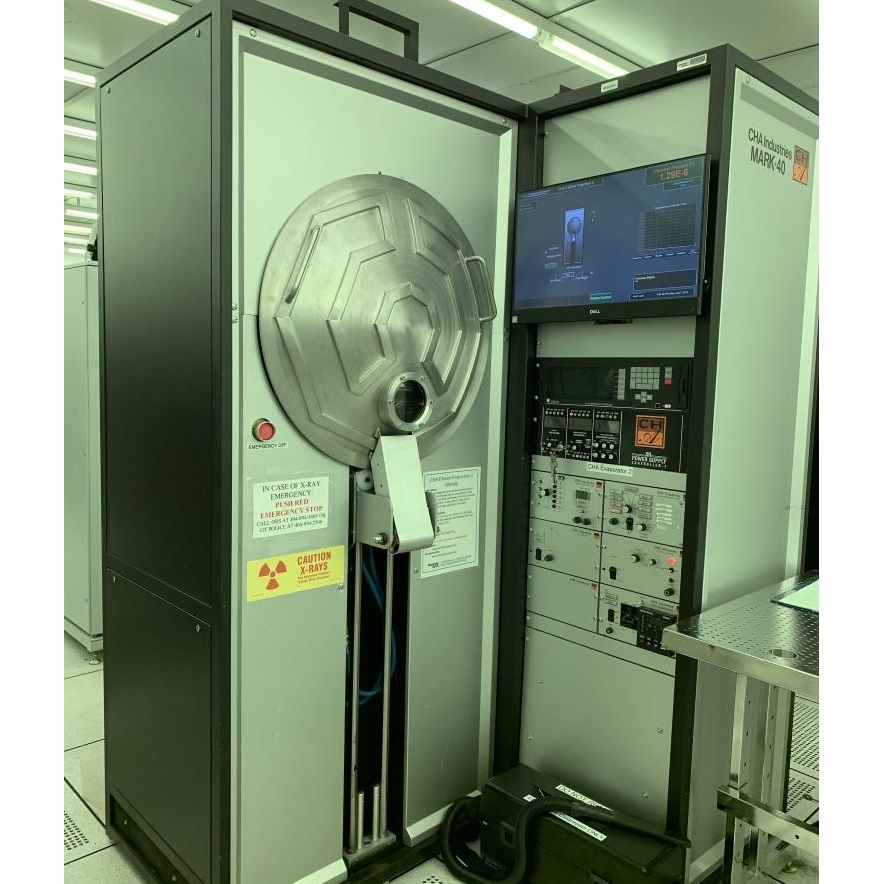

Equipment Description

The electron beam CHA Modified Mark-40 E-beam 2 evaporator is used to coat samples with various metals. A high-intensity beam of electrons is focused on the center of a crucible containing the material to be evaporated. The energy from the electron beam melts a region of the source metal. Material evaporates from the source and covers the sample with a thin layer.

Unlike sputtered films, evaporators only coat the surface facing away from the substrate. E-beam evaporators will provide very little coating to the sides of any features that are perpendicular to the surface of the substrate. In a typical process, the chamber is pumped down to a pressure of 5 x 10 -7 Torr. Typical deposition rates range from two to five angstroms per second. Typical thickness ranges from 10s of nanometers up to a micron.

Capable of evaporating: Titanium (Ti), Chrome (Cr), Gold (Au) , Nickel (Ni), Aluminum (Al), Copper (Cu) , Iron (Fe), Silver (Ag), Palladium (Pd), Other metals*

Manufacturer: CHA Industries

Model Number: Mark 40

Room Number: 1279

Radiation Safety Required: Yes

| Institute |

Georgia Tech |

| Department |

IEN - Micro/Nano Fabrication Facility |

Sub Tool Of  |

Marcus Inorganic Cleanroom |

System Components and Data

System Components: Ion gauge, valve controller, IC5/Deposition controller, crucible selector, power supply controller, XY sweep, shutter and hoist control

Specifications:

- Sample size based on sample holder -

- Flat Plate: Pieces to 12"

- 4" specific holder - holds three 4" wafers at a time

- 2" specific holder- up to 20 samples (dome shape)

Miscellaneous: The E-beam system holds six separate evaporation sources, allowing for evaporation of multiple materials in a single run. It has the capability to process a variety of sample sizes ranging from less than 1 cm2 to 4" wafers. It uses a cryo-pump for rapid pump down. Electron beam power is automatically controlled for uniform evaporation with little operator work. The E-beam system can process up to 20 3" (or less) samples simultaneously using a multiple-sample dome wafer holder

Metallization Calibration Data: (Updated Jan 2020)

| |

Z-Ratio |

Tooling Factor |

| Ti |

0.628 |

168.0 |

| Cr |

0.305 |

231.7 |

| Ni |

0.331 |

176.1 |

| Fe |

0.349 |

100.0 |

| Au |

0.381 |

166.4 |

| Al |

1.080 |

156.3 |

| Cu |

0.437 |

150.0 |

| Ag |

0.529 |

180.0 |