| | - Log into the CMOS Clean Station and Semitool Spin Rinse Dryer through the access controller on the wall.

|

| - Power on the controllers for the Piranha tank and the SC-II tank.

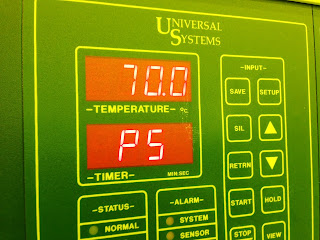

- Check the settings on the controller: 120C for 10 min on the Piranha tank, and 70C for 10 min on SC-II tank.

|

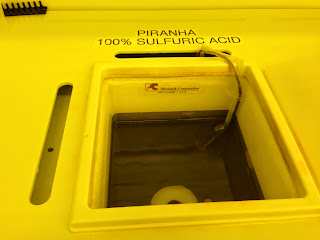

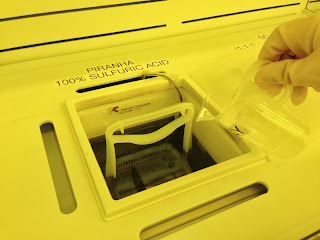

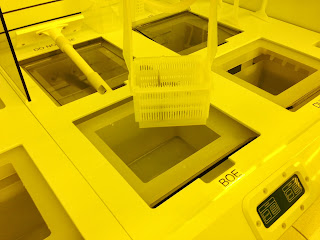

| - Check the liquid levels

- in the Piranha tank and BOE tank

- DO NOT use it when the liquid level is lower than 50% or higher than 75% of the total tank depth.

- Report to cleanroom staff if there is a problem.

|

| - Check the scheduler of the SC-II tank to see if any user has used it within the last 3 hours.

- If yes, you can use it

- If no, you need to drain the solution inside and refill the tank with fresh chemicals.

|

| - Start the temperature ramping for the Piranha tank through the controller.

- Make sure the lid is on the tank.

|

| - Put on personal protective equipment.

|

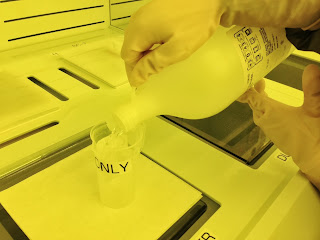

| - Refill the SC-II tank if needed.

- First, drain the solution in the tank through the controller.

- Then stop the draining, and fill the tank with 1 gallon of DI water, 900mL of H2O2 and 900mL of HCl using a Teflon volumetric beaker.

- Cover the tank with the lid and rinse the beaker with DI water 3 times.

|

| - Start the temperature ramping for the SC-II tank through the controller.

|

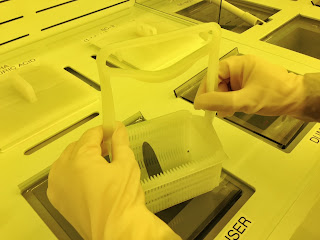

| - Load wafers into a Teflon wafer boat with the vacuum picker attached to the station.

- Make sure the handle fits tightly on the boat.

|

| - Measure 100 mL of H2O2 in the Teflon volumetric cylinder or beaker

|

| - Wait until the Piranha tank reaches 120C

- Then remove the lid and submerge the wafer boat inside the Piranha tank.

|

| - Gently pour the 100 mL of H2O2 into the Piranha tank. Rinse the used container with DI water for 3 times.

- Start the timer on the Piranha tank controller.

|

| - After the timer finishes and alarms, remove the wafer boat from the Piranha tank and immediately put it into the dump rinser.

- Start the rinser.

- Cover the rinser with the lid to prevent spilling.

- Ensure the cycle number is greater than or equal to 5.

|

| - When the rinsing cycle finishes, check the temperature on the SC-II tank controller to make sure it reaches 70C.

- Remove the wafer boat from the dump rinser and submerge the wafer boat into the SC-II tank.

- Start the timer on the SC-II tank controller

|

| - After the timer finishes and alarms, remove the wafer boat from the SC-II tank and immediately put it in the dump rinser.

- Start the rinser.

- Cover the rinser with the lid to prevent spilling.

- Ensure the cycle number is greater than or equal to 5

|

| - When the rinsing cycle finishes, remove the wafer boat from the dump rinser and submerge the wafer boat into the BOE tank.

- Start a personal timer.

|

| - After 30 seconds, remove the wafer boat from the BOE solution.

- While holding the boat over the solution, watch the wafer surface to see whether it is hydrophilic or hydrophobic.

- If the wafer surface is still hydrophilic, do an extra 30 sec clean.

|

| - When the BOE clean is done, remove the wafer boat from the BOE tank, immediately put it in the dump rinser.

- Start the rinser.

- Cover the rinser with the lid to prevent spilling.

- Make sure the cycle number is greater than or equal to 5.

|

| - When the rinsing cycle finishes, remove the wafer boat from the dump rinser and then load it into the Semitool Spin Rinse Dryer.

- Make sure the "H" side of the boat faces inside the chamber.

- Start the tool.

|

| - Remove the wafer boat from Semitool Spin Rinse Dryer when the process is done.

|

| - Remove all personal protection equipment.

|

| - Clean up the CMOS Clean Station with texwipes.

- Put all the lids on the tanks, and make sure there are no spills left on the bench.

|

| - Power off all the controllers.

|

| - Log off the CMOS Clean Station and the Semitool Spin Rinse Dryer through the access controller on the wall.

|